Xcheck DCM

The modern Xcheck DCM camera system monitors the feeder of the die cutter and thus closes an existing gap in quality monitoring. Inspection in the die cutter offers many advantages. For example, under-mixing of die-cut sheets is detected. The early detection of under-mixing in the process ensures less downtime and increases your productivity

- Simple integration

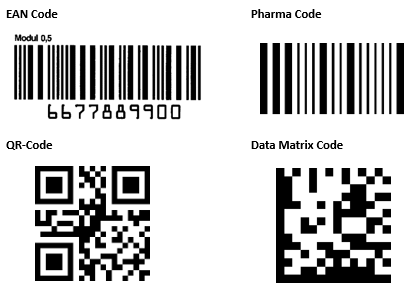

- Detection of 1D and 2D codes

- 100% quality control of all punched sheets

- For the front and back of the sheet

- Ready for future quality control requirements

Sustainability

Resource-efficient for increased sustainability

Fast setup for perfect production startup

Minimises cleaning cycles

Reduces production downtime by means of quality assurance and product tracking

Dot application reduces glue consumption

Developed for greater reliability in production

Fail-safe principle

100% quality control

Perfect adhesive application

Production data networking and analysis

Reliability

Folding Carton Production - See for yourself!