Electromagnetic Application heads

Baumer hhs offers everything for the application and processing of hot melt adhesives. The systems and components are used in many industrial applications.

From energy-efficient melters to long-life electrical application heads, Baumer hhs is your one-stop partner.

The precision of electric. Powerful like pneumatics!

Baumer hhs’s new PXH 1000 is an electric hot melt applicator that raises the bar in industrial gluing: high switching frequency, precision cut-off behaviour and maximum flexibility in selecting adhesives.

- Maximum availability with over 1 billion switching operations

- Short actuation times and 450 Hz application frequency

- Maximum safety due to integrated overtemperature switch

- Highest flexibility up to 7,000 mPa.s

- Closing force like pneumatic applicators

Download data sheet

Technical data

| Specification | Value | Unit |

|---|---|---|

| Temperature range | 0-200 | °C |

| Temperature monitoring | Pt 100 | |

| Switching frequency | 450 | Hz |

| Connection | 15 pole plug | |

| Hose connection | 1/2" UNF | |

| Adhesive pressure | 80 | bar |

| Adhesive viscosity | max. 7.000 | mPa.s |

| Noise emission | <70 | dB |

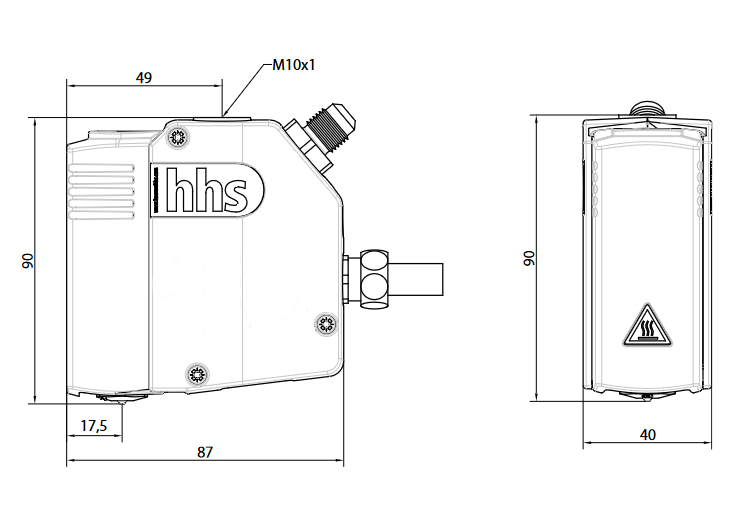

The hot melt head for the smallest dots at the highest machine speed

The tesla pro electromagnetic application head stands for maximum performance in packaging production. With its high availability and long service life, it helps to minimise production costs and make production more sustainable.

- Maximum availability with over 1 billion switching operations

- Short actuation times and 600 Hz application frequency

- Maximum safety due to integrated overtemperature switch

- Highest flexibility up to 5,000 mPa.s

Technical data

| Specification | Value | Unit |

|---|---|---|

| Temperature range | 0-200 | °C |

| Temperature monitoring | Pt 100 | |

| Switching frequency | 600 | Hz |

| Connection | 15 pole plug | |

| Hose connection | 1/2" UNF | |

| Adhesive pressure | 80 | bar |

| Adhesive viscosity | max. 5.000 | mPa.s |

| Noise emission | 65 | dB |

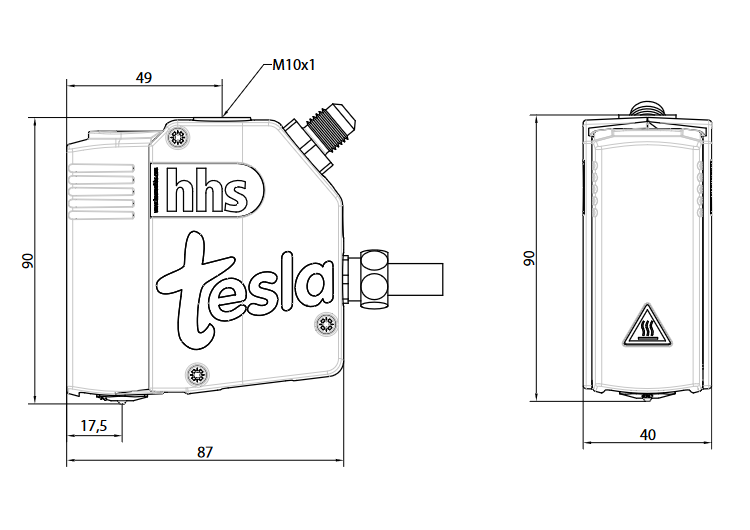

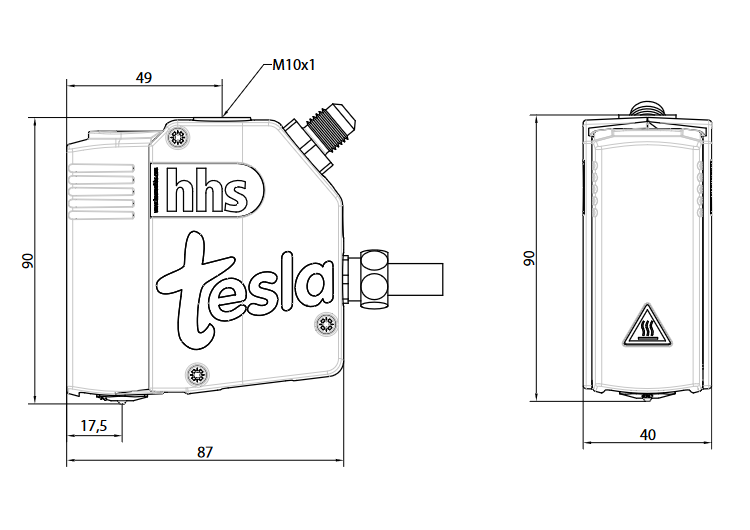

The innovative hot melt head controled via PLC 24V

The tesla evo provides the packaging industry with a powerful electromagnetic application head that can be controlled directly via the machine controller. The immense advantages of electromagnetic valves can now also be used in end-of-line packaging. This reduces production costs through adhesive savings and maximum availability of the packaging machines.

- Maximum availability with over 1 billion switching operations

- Simple control via SPS 24V

- Maximum safety due to integrated overtemperature switch

- Maximum flexibility up to 5,000 mPa.s

Technical data

| Specification | Value | Unit |

|---|---|---|

| Temperature range | 0-200 | °C |

| Temperature monitoring | Pt 100 | |

| Switching frequency | 135 | Hz |

| Connection | 15 pole plug | |

| Hose connection | 1/2" UNF | |

| Adhesive pressure | 80 | bar |

| Adhesive viscosity | max. 5.000 | mPa.s |

| Noise emission | 65 | dB |

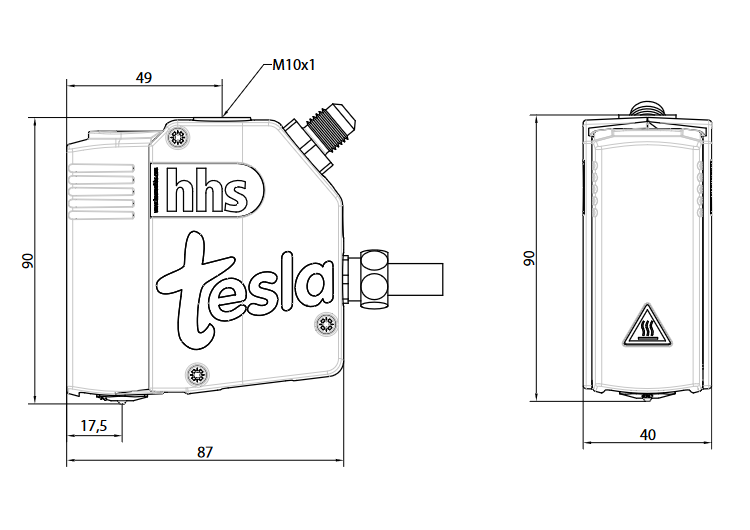

The innovative application head for use on third-party systems

The tesla go provides the packaging industry with a powerful electromagnetic application head that can be controlled directly via the machine controller. The immense advantages of electromagnetic valves can now also be used in end-of-line packaging. This reduces production costs through adhesive savings and maximum availability of the packaging machines.

- Maximum availability with over 1 billion switching operations

- Simple control via PLC 24V

- Maximum safety due to integrated excess temperature cut-off

- Maximum flexibility up to 5,000 mPa.s

- Easy integration due to competition-compatible connections

Technical data

| Specification | Value | Unit |

|---|---|---|

| Temperature range | 0-200 | °C |

| Temperature monitoring | Ni 120 | |

| Switching frequency | 135 | Hz |

| Connection | Stecker für den Betrieb an Fremdsystemen | |

| Hose connection | 9/16-18 UNF | |

| Adhesive pressure | 80 | bar |

| Adhesive viscosity | 5.000 | mPa.s |

| Noise emission | 65 | dB |